PP ANALYSIS Poland’s ‘Orka’ submarine program. Part 1. The HDW Class 212A 214 submarines – ThyssenKrupp Marine Systems

Autor foto: Domena publiczna

Poland’s ‘Orka’ submarine program. Part 1. The HDW Class 212A/214 submarines – ThyssenKrupp Marine Systems

June 20, 2017

Author: Rafał Lipka

PP ANALYSIS Poland’s ‘Orka’ submarine program. Part 1. The HDW Class 212A 214 submarines – ThyssenKrupp Marine Systems

Autor foto: Domena publiczna

Poland’s ‘Orka’ submarine program. Part 1. The HDW Class 212A/214 submarines – ThyssenKrupp Marine Systems

Author: Rafał Lipka

Published: June 20, 2017

Pulaski Policy Paper no 12, June 20, 2017

On March 9, 2017, the Pulaski Foundation organised the first out of a three seminars concerning technologies and combat capabilities of conventional submarines competing in the ‘Orka’ program, which is intended to select modern submarine design for the Polish Navy. The first seminar was dedicated to German experiences in terms of conventional submarines. The Pulaski Foundation organized the seminar in cooperation with ThyssenKrupp Marine Systems (TKMS) and the representatives of the Germany Navy. Participants of the seminar, including experts from research centres and public institutions, were presented with a detailed information on the German offer. The procurement of German submarines designed by TKMS has been analysed several years ago by the Polish Armed Forces. In June 2008, a Polish Navy delegation paid a visit to the shipyard in Germany in order to observe the construction process of the HDW 214 Class submarine and compare these vessels to French and Swedish projects. The German company, however, has finally decided to offer the HDW 212A Class submarines (which is based on different design and requirements than the 214 Class) together with the 214 Class submarines.

Undoubtedly, ThyssenKrupp Marines Systems is the most experienced company in the ‘Orka’ program as far as construction of conventional submarines is concerned. The 212A Class has been specifically designed to conduct operations in the littoral zone in order to meet the requirements of the German Navy. Therefore, the specifications of these vessels, such as the use of non-magnetic steel, were based on different approach compared to the HDW 214 Class. So far TKMS has built 10 vessels of this class: 6 boats were commissioned in the German Navy and further 4 vessels in the Italian Navy (the last, fourth is expected to be commissioned in late 2017). It is also worth noting that Norway, which had been facing a similar requirements as the Polish Navy, chose the German offer. In early 2017, the Norwegian Ministry of Defence announced that Germany had been selected as a partner in construction of new submarines. Norway plans to purchase new vessels with the German government. According to the current plan, Germany will buy two 212A Class submarines whereas Norway is interested in purchasing four vessels. The contract with ThyssenKrupp Marine Systems is expected to be signed in 2019. Consequently, the German Navy will significantly extend its capabilities with the fleet of 8 vessels of the 212A Class submarines. Norway and Poland expect a technology transfer to boost their national industries and increase production capabilities. However, it is also worth emphasising that the Norwegian approach provides an opportunity to reduce the unit cost thanks to the large-scale procurement.

The 214 Class also represents an interesting approach to submarine design. The 212 Class is based on multi-mission concepts, which intended to extend the capabilities of the vessel in various environments, including expeditionary operations. The 214 Class is larger than the 212 Class and made from high-performance steel which increases its depth ratings. The submarine was developed to meet requirements of foreign customers, including possibility of constructing vessels overseas under a licence. The 214 Class submarines have been introduced (or are currently under construction) in the following countries: Greece (4 vessels in total; the first was built in Germany, latter 3 in Greece); South Korea (9 built under licence in two batches; the first 6 vessels from the first batch are expected to be launched in 2018); Portugal (2 vessels designated as the 209PN Class, both built in Germany); and Turkey (6 vessels on order; construction of all vessels in Turkey under licence; most of equipment will be delivered by the Turkish defence industry). It is also worth mentioning the two boats of the 218SG Class ordered by Singapore, which are currently under construction in the German shipyard in Kiel.

212A Class: Specification

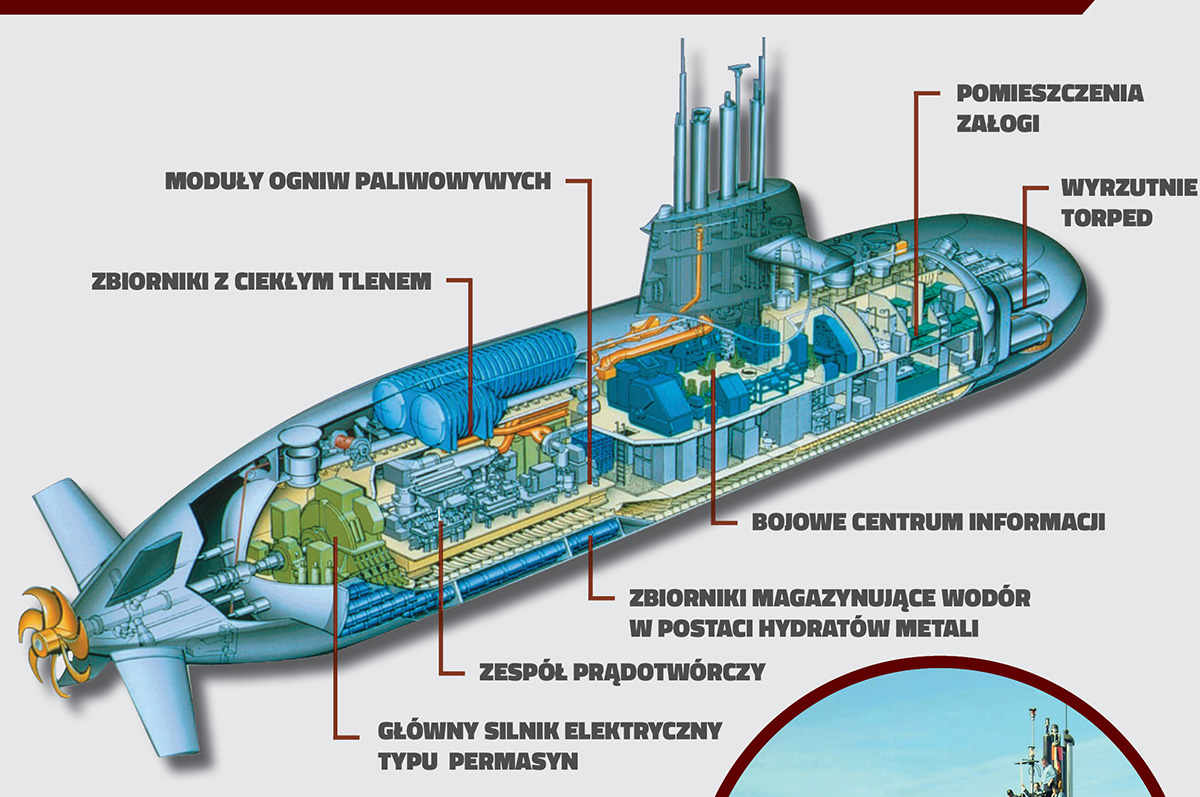

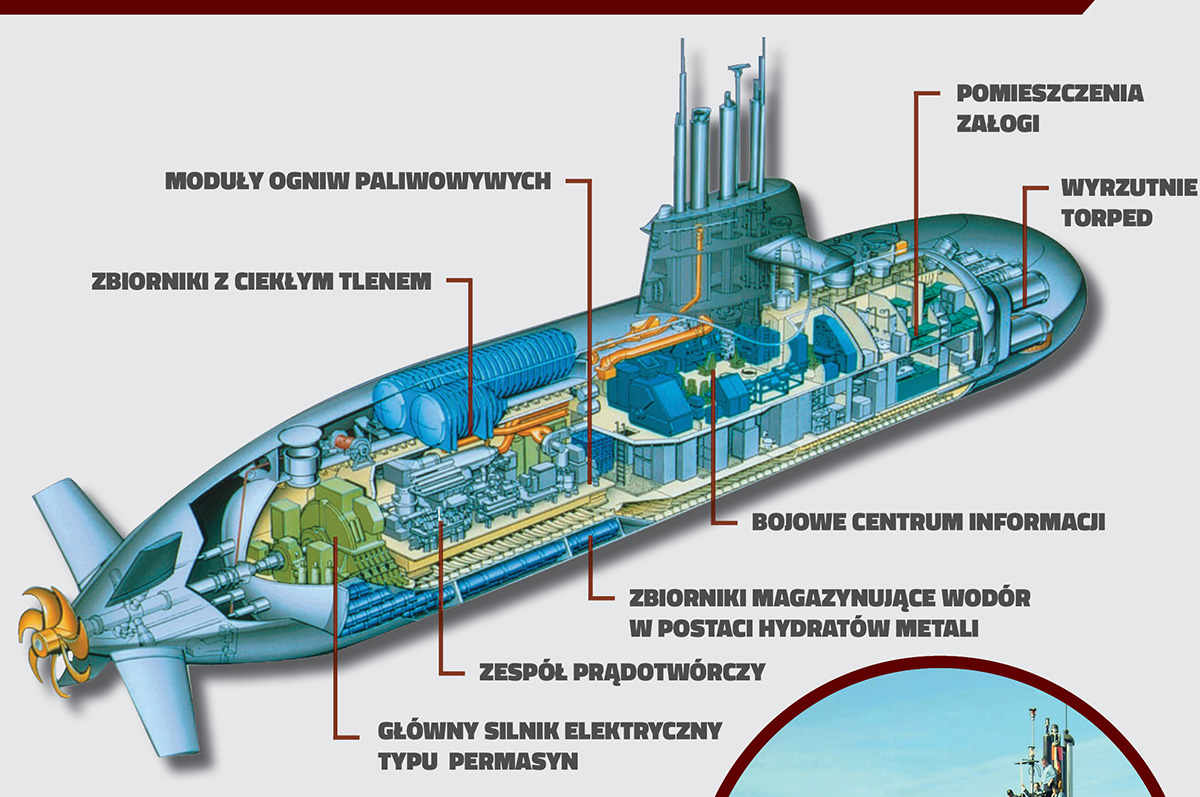

The 212A Class was specifically designed to face specific hydrological characteristics of the Baltic Sea. TKMS applied stealthy design to reduce acoustic (sonar) cross-section (SCS) of the submarine. Given its relatively small dimensions and modern equipment, the submarine is capable to remain undetectable in the littoral zone. The 212A Class submarines have been commissioned in the German (6 vessels) and Italian (4) Navies. The dimensions of the submarine are as follows: length 56-58 m (depending on the batch); diameter from 5.7 m (stern) to 7 m (bow); displacement 1,450–1,500 tonnes. The boat is based on ‘one-and-a-half’ hull design and its pressure hull is made from non-magnetic steel, which is certainly an important operational asset. The use of non-magnetic steels not only reduces the risk of detection but also provides the opportunity to conduct naval operations in a mine warfare environment. Furthermore, the non-magnetic steel allows to optimize use of demagnetization systems and save the electrical energy. The external (light) hull is made of composite materials, which are also used to build horizontal and vertical rudders and cover sensor systems. Six torpedo tubes (533 mm) are located in the bow. The boat can carry 12 torpedoes in total, however, the tubes can be also integrated with various missiles. The representatives of ThyssenKrupp Marines System point out that the company’s experience is based on the construction of 55 submarines in the shipyard in Kiel, which were integrated with various types of missiles. Furthermore, according to press releases, it seems likely that six of these vessels were integrated with cruise missiles. Despite the fact that the German and Italian Navy have not made a decision on the integration of their vessels with cruise missiles, the TKMS ensures that the 212A Class submarines can be equipped with weapons chosen by the Polish Ministry of Defence.

The 212A Class was specifically designed to face specific hydrological characteristics of the Baltic Sea. TKMS applied stealthy design to reduce acoustic (sonar) cross-section (SCS) of the submarine. Given its relatively small dimensions and modern equipment, the submarine is capable to remain undetectable in the littoral zone. The 212A Class submarines have been commissioned in the German (6 vessels) and Italian (4) Navies. The dimensions of the submarine are as follows: length 56-58 m (depending on the batch); diameter from 5.7 m (stern) to 7 m (bow); displacement 1,450–1,500 tonnes. The boat is based on ‘one-and-a-half’ hull design and its pressure hull is made from non-magnetic steel, which is certainly an important operational asset. The use of non-magnetic steels not only reduces the risk of detection but also provides the opportunity to conduct naval operations in a mine warfare environment. Furthermore, the non-magnetic steel allows to optimize use of demagnetization systems and save the electrical energy. The external (light) hull is made of composite materials, which are also used to build horizontal and vertical rudders and cover sensor systems. Six torpedo tubes (533 mm) are located in the bow. The boat can carry 12 torpedoes in total, however, the tubes can be also integrated with various missiles. The representatives of ThyssenKrupp Marines System point out that the company’s experience is based on the construction of 55 submarines in the shipyard in Kiel, which were integrated with various types of missiles. Furthermore, according to press releases, it seems likely that six of these vessels were integrated with cruise missiles. Despite the fact that the German and Italian Navy have not made a decision on the integration of their vessels with cruise missiles, the TKMS ensures that the 212A Class submarines can be equipped with weapons chosen by the Polish Ministry of Defence.

214 Class: Specification

Development of the 214 Class was based on proven concepts of the 209 Class. The submarines were designed specifically to meet the requirements of the export markets. Currently, there are 14 vessels of this class in service, including 6 submarines commissioned in the fleets of two NATO member states and 9 more under construction. The 214 Class submarines are larger than the 212A Class (length: 65 m; displacement: 1,800 tonnes) with a slightly narrower hull (6.3 m). The 214 Class is equipped with 8 torpedo tubes capable of launching anti-ship missiles. It is also worth emphasizing that both the 214 and 209 Classes have been integrated with the Harpoon UGM-84 anti-ship missiles. The submarine has a crew of 27 sailors and officers, however, the boat can accommodate further 3 sailors/officers and 5 special forces soldiers. The propulsion is based on the concept used in the 212A Class, that is the PERMASYN motor with fuel cell modules. The 214 Class is equipped with two fuel cell modules (2x120kW) and consequently the total power supplied by the AIP system is lower compared to the 212A Class, however, this parameter does not affect the capabilities of the 214 Class submarines. The pressure hull is constructed of HY100 steel, in contrast to the 212A Class. In consequence, the producer had to implement a demagnetization system. On the other hand, the use of HY100 steel increases the depth ratings of the 214 Class (according to the current information, the boat has a maximum operating depth of 350–400 m). This parameter can be perceived as an advantage if the submarine is expected to operate outside of the Baltic Sea. Moreover, it is worth noting that the submerged boat will use the AIP system, which seems to be problematic in French and Swedish submarines since these vessels need to discharge exhaust gases mixed with sea water overboard.

Development of the 214 Class was based on proven concepts of the 209 Class. The submarines were designed specifically to meet the requirements of the export markets. Currently, there are 14 vessels of this class in service, including 6 submarines commissioned in the fleets of two NATO member states and 9 more under construction. The 214 Class submarines are larger than the 212A Class (length: 65 m; displacement: 1,800 tonnes) with a slightly narrower hull (6.3 m). The 214 Class is equipped with 8 torpedo tubes capable of launching anti-ship missiles. It is also worth emphasizing that both the 214 and 209 Classes have been integrated with the Harpoon UGM-84 anti-ship missiles. The submarine has a crew of 27 sailors and officers, however, the boat can accommodate further 3 sailors/officers and 5 special forces soldiers. The propulsion is based on the concept used in the 212A Class, that is the PERMASYN motor with fuel cell modules. The 214 Class is equipped with two fuel cell modules (2x120kW) and consequently the total power supplied by the AIP system is lower compared to the 212A Class, however, this parameter does not affect the capabilities of the 214 Class submarines. The pressure hull is constructed of HY100 steel, in contrast to the 212A Class. In consequence, the producer had to implement a demagnetization system. On the other hand, the use of HY100 steel increases the depth ratings of the 214 Class (according to the current information, the boat has a maximum operating depth of 350–400 m). This parameter can be perceived as an advantage if the submarine is expected to operate outside of the Baltic Sea. Moreover, it is worth noting that the submerged boat will use the AIP system, which seems to be problematic in French and Swedish submarines since these vessels need to discharge exhaust gases mixed with sea water overboard.

Conclusions

Given the fact that Norway chose Germany as its strategic partner in construction of new submarines, the Polish Ministry of Defence ought to continue and develop further intergovernmental cooperation in terms of the military procurement. Furthermore, the common procurement of the military equipment provides an opportunity to reduce the unit cost and life cycle costs. It is also worth considering to strengthen bilateral cooperation with the German Navy as far as the submarine training systems are concerned. Given the entire infrastructure and the advanced 212A Class simulators in Germany, this aspect seems to be particularly important.

ThyssenKrupp Marine Systems declares that all new vessels for the Navy can be built in Polish shipyards. However, the producer points out that the construction cost will be based on the technologies, which Polish government wants to purchase to extend the capabilities of the defence industry. It seems clear that the construction of new submarines in Germany would be cheaper. Given the high costs related to the procurement of new submarines, the Polish Ministry of Defence ought to perceive the purchase of new technologies for the national industry as a priority, despite the unit cost of one vessel built in Poland or Germany. Furthermore, ThyssenKrupp Marine Systems has proved its experience as far as the international cooperation is concerned. Therefore, the cooperation with Germany seems to a chance for the Polish military industry to modernize by purchasing crucial technologies and using the experience from the construction of new submarines with TKMS. Furthermore, it is also worth noting an opportunity for the Polish state-owned companies within the Polish Armaments Group (Polska Grupa Zbrojeniowa SA) to join the supply chain of ThyssenKrupp Marines Systems and its subsidiary companies. The representatives of TKMS emphasize the significance of the Polish-German cooperation (such as projects conducted in cooperation with the University of Technology in Warsaw and Gdańsk). However, the Polish administration ought to define a range of technology transfer and select specific licences for military companies to broaden their capabilities in future.

The main disadvantage of the German and Swedish offers is the procurement of cruise missiles from the United States and, subsequently, the integration of these missiles with new submarines. In the case of French submarines the cruise missiles are an integral part of the offer document. However, the final price of these missiles can be much more problematic. The costs of French missiles are expected to be much higher compared to Tomahawk missiles due to the small-scale production of MdCN. An estimated cost of the Tomahawk missile for the United States Armed Forces is USD 1.5 mln per missile (it is worth noting that the price for the Polish Armed Forces is expected to be higher). According to the information publish by the French Senate, the development and procurement program of 200 MdCN missiles is worth over EUR 1.2 bln (2011). The unit cost (excluding development costs) is expected to reach EUR 2.48 mln. ThyssenKrupp Marines Systems declares to take the responsibility for the integration of American missiles with the 212A/214 Class submarines.

The main disadvantage of the German and Swedish offers is the procurement of cruise missiles from the United States and, subsequently, the integration of these missiles with new submarines. In the case of French submarines the cruise missiles are an integral part of the offer document. However, the final price of these missiles can be much more problematic. The costs of French missiles are expected to be much higher compared to Tomahawk missiles due to the small-scale production of MdCN. An estimated cost of the Tomahawk missile for the United States Armed Forces is USD 1.5 mln per missile (it is worth noting that the price for the Polish Armed Forces is expected to be higher). According to the information publish by the French Senate, the development and procurement program of 200 MdCN missiles is worth over EUR 1.2 bln (2011). The unit cost (excluding development costs) is expected to reach EUR 2.48 mln. ThyssenKrupp Marines Systems declares to take the responsibility for the integration of American missiles with the 212A/214 Class submarines.

Given the Greek experience during the construction of HS ‘Papanikolis’, which started in 2011, there is no denying that the development of new submarines is always exposed to certain risks. According to the representatives of ThyssenKrupp Marine Systems the technical problems that were plaguing the first 214 Class submarine should be perceived as a common issue as far as the prototype is concerned. The construction of HS ‘Papanikolis’ has been causing controversy for several years, however, the objections of the Greek Navy were raised against the boat built in Germany. Currently, it seems impossible to determine whether the delay was caused by the producer. Therefore, the Polish Ministry of Defence ought to take into consideration these issues while analysing the submarines offered in the ‘Orka’ program.

Recommendations

1. The design of the 212A Class is based on different operational requirements from the 214 Class. The 212A class submarines are the optimum solutions for conducting operations in the Baltic Sea owing to their specifications and design, including the use of non-magnetic steel. According to the producer, the magnetic signature of the 212A Class is reduced by 40 percent compared to the 214 Class, assuming that both boats are similar in dimensions and displacement. In fact, the 212A submarine has an even lower magnetic signature thanks to the use of demagnetization systems and non-magnetic steel.

2. Undoubtedly, selection of the 212A Class submarines would strengthen the Polish-German cooperation, which seems to be a significant advantage of the deal with ThysseKrupp Marines Systems. It is also worth noting that the German government has offered to lease one submarine to the Polish Navy. Polish sailors could be trained at the submarine training centres in Germany, therefore, the deal with TKMS should be also perceived as an opportunity to reduce Navy’s operational costs (e.g. common training programs). Furthermore, it is necessary to emphasize that the Polish Navy can be equipped with a temporary boat based on similar design as Navy’s future submarines, which will be an important addition to the fleet and a chance to boost the training program.

3. The use of the Air Independent Propulsion based on fuel cell modules seems to be more efficient than a Stirling engine (the main benefit of fuel cells is higher energy conversion efficiency), however, it is crucial to analyze the operational costs of this technology (particularly maintenance and repairs) and the infrastructure which is necessary to supply new submarines. One of the most important advantages of the fuel cell systems is a lack of moving parts, therefore, this design significantly reduces the acoustic signature of a submarine. Furthermore, given the closed-cycle, air-independent propulsion system, the submarines do not need to discharge exhaust gases mixed with sea water overboard and, in turn, can evade detection.

4. The main issue, however, related to both German and Swedish submarines, is the procurement and integration of cruise missiles. Apart from the MdCN, the Tomahawk missile is the only system of this class available, therefore, Poland ought to purchase these weapons directly from the United States. Consequently, it is difficult to compare the proposals in the ‘Orka’ program objectively, particularly in terms of the procurement costs. The Ministry of Defence should also take into consideration technological difficulties related to the integration of German and Swedish submarines with American cruise missiles. Moreover, the Polish Ministry of Defence ought to carry out detailed analyses and discuss these issues with the US administration in order to estimate the final cost of the submarine and missiles procurement. Given the fact that DCNS offers submarines equipped with MdCN missiles, the French company seems to possess a significant advantage in this field.

5. A strong negotiating position of ThyssenKrupp Marine Systems may lead to certain difficulties as far as the technology transfer for the Polish industry is concerned. It is worth noting that one of TKMS’s competitors– SAAB –has lost a potential customer, which selected the German company as a partner in the submarine construction program. Norway’s decision to purchase new submarines with the German government will certainly affect the position of SAAB’s representatives. The Swedes may look for a compromise in terms of the industrial cooperation and offer more than their German competitors. The Polish administration ought to use this matter during the negotiations with the Swedish producer. On the other hand, it is worth noting that Norway’s policy (common acquisition of the 212CD Class submarines with Germany) should be perceived as an opportunity to reduce the unit cost of a boat owing to the scale of procurement.

6. The experience of the German company in the construction of various submarines, which were commissioned to the naval forces around world (including NATO member states), is certainly the strength of ThyssenKrupp Marine Systems. Furthermore, the German company announced that all boats of the Polish Navy may be built in Poland. The 212A/214 Class submarines proved to be well designed, therefore, the deal with ThyssenKrupp Marine Systems should reduce the risks related to the construction of the prototype, which are usually plagued with technical problems at the very beginning. However, the technical specifications and capabilities of the submarines should remain the crucial part of the producers’ proposals.

Author: Rafał Lipka, Analyst of the ‘Defence and Security Programme’ at the Casimir Pulaski Foundation